How can you mitigate supply chain risks with trending supply chain risk management strategies? Read on to gain valuable insights that define how businesses will thrive amidst uncertainties. Start planning for 2024!

Introduction

Undoubtedly, 2023 was another turbulent year with labor shortages, increased pay demands, global geopolitical and trade conflicts, and pressure to decarbonize transportation. Businesses throughout different industries are looking to the supply chain industry for assistance in improving and optimizing how goods are moved and stored between supply chain nodes. Meanwhile, supply chain companies deal with such critical concerns. This blog sheds light on emerging supply chain risks and the risk mitigation strategies to follow. Here are six practical strategies that we predict are solid for risk mitigation.

Potential Risks and Disruptions for the Supply Chain Industry in 2024

What do the future supply chain ecosystems look like? What are their primary obstacles and risks, and what can supply chain businesses do to bolster their resilience? To understand the solutions, firstly, we must understand the risks and other factors that have directly impacted the supply chain in 2023:

| Risks | Details |

| Cyber Risks | Supply chain cyber risks involve vulnerabilities in interconnected systems leading to:

Supply chain cyber risks involve vulnerabilities in interconnected systems leading to:

Such risks are posing a significant challenge to business continuity and data integrity. |

| Economic Risks | Economic risks in the supply chain encompass:

Disruptions in the supply chain, such as natural disasters or geopolitical events, can impact:

These factors can directly affect the overall economic stability of businesses operating within the supply chain. |

| Geopolitical Risks | Geopolitical risks in the supply chain involve potential disruptions arising from:

Shifts in policies, sanctions, or regulatory changes can impact:

Businesses need to navigate these uncertainties to ensure resilience and continuity in a dynamic geopolitical landscape. |

| Climate and Environment | These risks encompass disruptions in transportation due to:

Businesses face challenges in mitigating environmental impact, adapting to changing conditions, and meeting evolving sustainability expectations from consumers and regulators. |

| Pandemics | Pandemics pose significant challenges to the supply chain by:

|

| Increased Product Complexity | Increased product complexity in the supply chain introduces risks such as:

|

| Onshoring | Onshoring in the supply chain can pose risks such as:

While it offers benefits like reduced lead times and increased control, onshoring requires careful consideration of economic factors and geopolitical stability. |

| Labor Shortage | Since industries and enterprises are interconnected, labor shortages in one sector can have a cascading effect on others. For example, according to the American Trucking Association, the industry’s current driver shortage of over 80,000 could expand to over 160,000 by the end of 2030. |

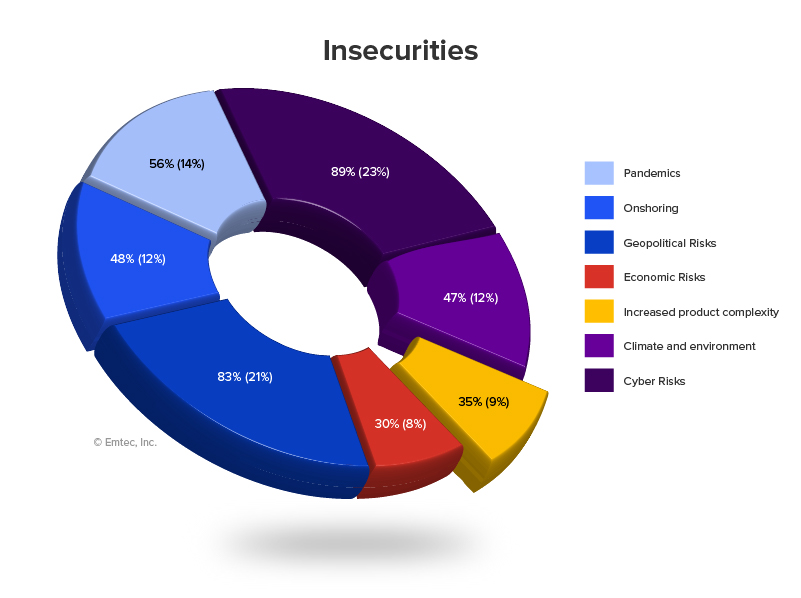

Let’s see what supply chain business professionals say about these risks becoming insecurities directly impacting the supply chain.

Struggling scenarios in managing these threats during the next 3-5 years are:

| Scenarios | Details |

| Shortage of Insurance and Risk Transfer Solutions | Limited coverage options, such as geopolitical events or pandemics, may not adequately address the diverse and evolving nature of these risks. |

| Shortage of Data, Knowledge, and Risk Understanding | Inadequate information on supplier vulnerabilities, market dynamics, and emerging risks can lead to poor decision-making. |

| Shortage of Risk Management Tools and Insights | Inadequate technological solutions and analytical tools limit the ability to identify, assess, and respond to potential disruptions. |

| Shortage of Budget | This may lead to gaps in contingency planning, resilience measures, and technology investments. |

| Shortage of Board Buy-in | Without top-level support, allocating resources, implementing proactive strategies, and integrating risk considerations into decision-making processes may face resistance. |

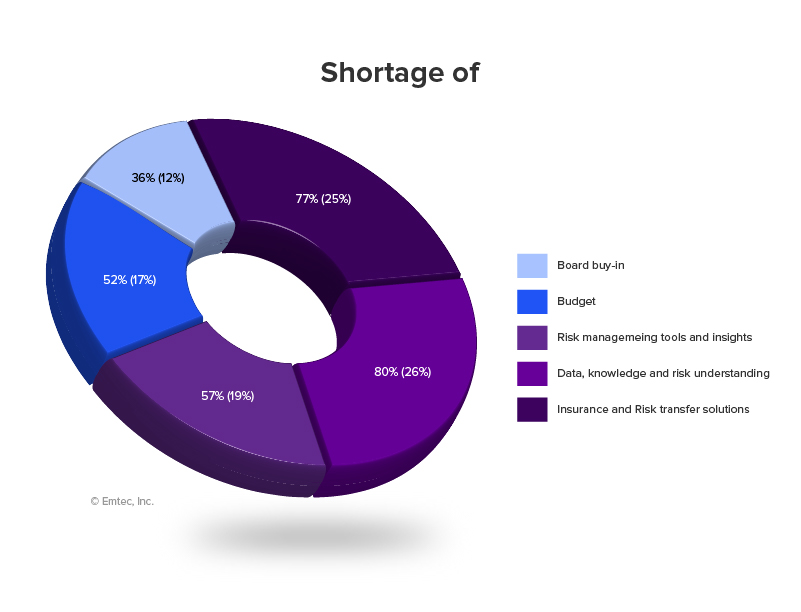

According to supply chain business professionals responding to these shortages, this is how each of these scenarios is prioritized:

Due to an aging driver workforce, concern over driver pay and quality of life, and regulatory constraints, the sector will need to recruit almost 1 million new drivers by the end of the decade to replace capacity and maintain growth. Slower production, skewed inventory levels, disturbed distribution, delayed delivery, and dissatisfied consumers can all result from an understaffed supply chain.

“72% of PwC survey respondents say their supply chains are at high or very high risk. However, only 39% of these organizations plan to raise their risk management investment during the next two years.” – PwC

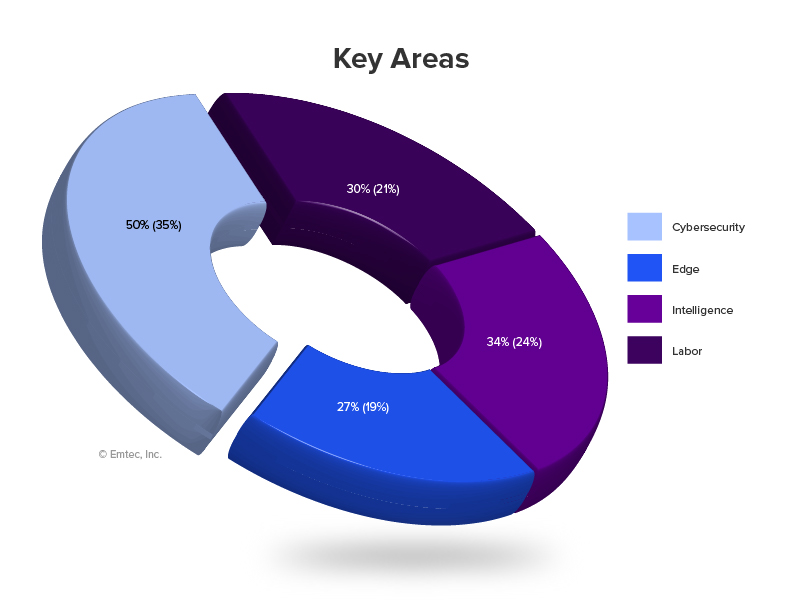

According to supply chain business professionals, the critical risks of focus that are encouraging them to invest in emerging technologies are:

Managing supply chain risks requires proactive planning and investment. Is your supply chain sophisticated enough to cope with such threats? If not, let’s understand what trending strategies you’ll have to adapt to in 2024.

Trending Strategies for 2024 to Mitigate Risk and Disruption

To future-proof the supply chain, ensure your plan includes the following trending strategies:

Establishing a Centrally Controlled Supply Chain Delivering End-to-End Visibility

Supply chain control towers are centralized platforms that offer real-time visibility and management of various supply chain activities. They integrate data from multiple sources, providing a comprehensive overview of the entire supply chain. Control towers enable better decision-making, proactive risk management, and streamlined stakeholder coordination, ultimately enhancing operational efficiency and resilience. Supply chain control towers can help businesses in the following ways:

| Details | Benefits |

| Supply chain control towers are based on intelligent technologies that help businesses capture, process, and use vast structured and unstructured data. | This enables supply chain businesses to centralize data and insights for enhanced and faster decision-making. |

| The digital hubs functioning under supply chain control towers bring together people, processes, and technologies. | This provides a 360-degree view of the supply chain network across all tiers of suppliers and routes to market. |

Even though over 57% believed effective supply chain management to be a competitive advantage and gaining such visibility had become the third-highest priority for all firms, only over 6% of responding organizations had accomplished their targets for end-to-end supply chain visibility. ~ GEODIS

Creating a Hyper-Personalized and Flexible Supply Chain

By deploying ML algorithms, businesses can achieve a hyper-personalized and flexible supply chain; let’s see how:

| Details | Benefits |

| With the help of ML-based tools, you can achieve insights that might go unnoticed otherwise. ML-based tools help supply chain businesses achieve unnoticed insights to identify trends for growth opportunities. |

These insights help minimize the risks of overstocking or stockouts, enhancing overall supply chain flexibility. |

| With real-time visibility into market data, your business will produce more significant insights, variation, and urgency in understanding and meeting demand requirements. | This proactive approach allows for swift adjustments to sourcing strategies and distribution channels, mitigating the impact of unforeseen disruptions. This is why several companies hyper-personalize order fulfillment by medium, service level, and locality. |

Utilizing Supply Chain Digital Twin and Scenario Planning

A supply chain digital twin, which is a virtual replica of the end-to-end supply chain, can help companies in the following ways:

| Details | Benefits |

| Businesses can evaluate potential outcomes by simulating different scenarios in the digital twin, such as sudden demand spikes, supplier disruptions, or transportation delays. | This proactive approach aids in identifying vulnerabilities and developing contingency plans. |

| Applying stress tests involves pushing the digital twin to its limits to assess how the supply chain performs under extreme conditions. | This helps identify critical points of failure and implement measures to enhance resilience. |

Utilizing the Actionable AI and Supply Chain Connection

Actionable AI can learn patterns based on previous judgments and experiences to respond to real-world situations. These responsive and adaptive capabilities can help in supply chain risk mitigation in the following ways:

| Details | Benefits |

| Actionable AI uses predictive analytics to forecast potential disruptions. ML algorithms can assess many factors, including supplier performance, market trends, and geopolitical events, to predict and prioritize potential risks. | This foresight allows for proactive risk mitigation strategies. |

| Actionable AI leverages historical data from past supply chain events, including disruptions, demand fluctuations, and the performance of suppliers. | By analyzing historical patterns, the AI system identifies correlations and learns from the outcomes of previous risk management strategies. |

| Actionable AI excels at pattern recognition, identifying subtle indicators of potential risks before they escalate. | The system can provide early warnings by recognizing patterns indicative of upcoming disruptions, allowing supply chain managers to implement preventive measures or contingency plans. |

Utilizing Supply Chain Intelligent Automation

Deploying intelligent automation can help supply chain risk mitigation in the following ways:

| Details | Benefits |

| Intelligent automation can digitize and streamline trade document creation, processing, and management, reducing manual errors and delays. | Ensuring accurate and timely documentation minimizes the risk of customs delays, fines, or regulatory non-compliance, contributing to a smoother flow of goods in the supply chain. |

| Automation tools can continuously monitor changes in free trade agreements and regulations, ensuring that trade activities comply with evolving legal requirements. | Automating FTA compliance checks reduces the risk of inadvertent violations, optimizes duty and tariff management, and preserves cost advantages associated with trade agreements. |

| Intelligent automation systems can calculate trade taxes and duties by applying up-to-date tax rates and rules. | Accurate and automated tax calculations minimize the risk of miscalculations or underpayments, avoiding financial penalties and ensuring compliance with tax regulations. |

Finding Multiple Routes to Market

Finding multiple routes to market for supply chain businesses can help in the following ways:

| Details | Benefits |

| Utilizing multiple suppliers and distribution channels reduces dependency on a single source, minimizing the impact of disruptions from a specific supplier or route. | Diversification enhances supply chain resilience by providing alternative options in case of supplier failures, transportation issues, or geopolitical challenges. |

| Supply chain integration allows for real-time monitoring of key supply chain metrics and the application of data analytics to identify patterns and trends. | By leveraging analytics, organizations can spot potential risk indicators, such as fluctuations in demand, supplier delays, or quality issues, and take preemptive actions to mitigate these risks. |

| Integrated ecosystems facilitate seamless communication and collaboration among supply chain partners. | In the face of changing conditions, such as market shifts or unforeseen disruptions, a well-integrated supply chain allows for dynamic decision-making and swift adaptations to minimize the impact on operations. |

| Integrated ecosystems enable better coordination with suppliers and alternative sourcing strategies. | In supply chain disruptions, organizations can quickly identify alternative sources for critical components or materials, reducing the risk of production delays. |

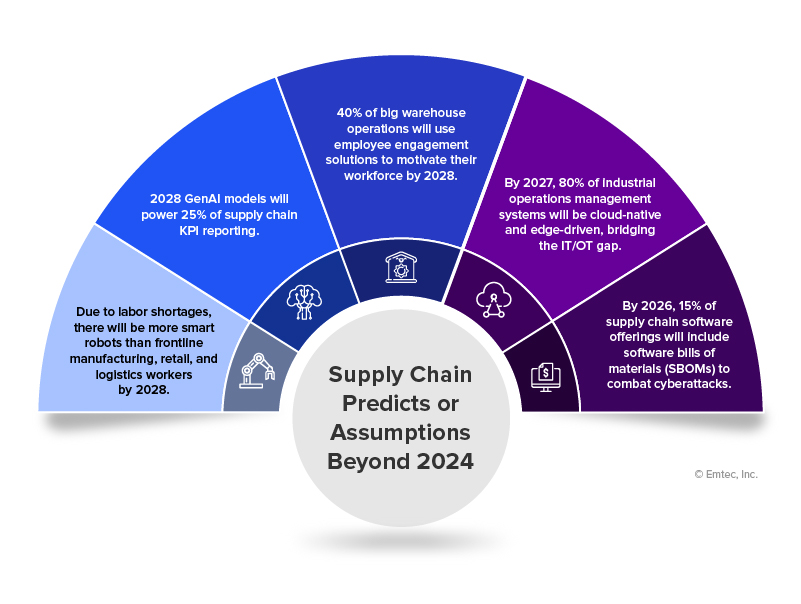

Supply Chain Predictions Beyond 2024

Apart from these strategies, Gartner has a few predictions that go beyond 2024 based on current risks, market shifts, and emerging technology trends:

Your supply chain business should begin preparing for these realities; the strategies we discussed here can help.

Conclusion

Designing a disruption-proof detailed plan to drive resiliency, relevancy, and responsibility is easier said than done. Putting data at the heart of the supply chain and deploying AI at a scale to create a connected and truly intelligent supply chain will require support to eliminate all the associated risks. This is where we can help. Bridgenext (former Emtec Digital) offers a free consultation session with our digital experts based on your risk mitigation strategies. All you need to do is reach out. Write to us to schedule the meeting.

References

supplychains.com/2023-logistics-supply-chain-risk-report/

www.dhl.com/global-en/home/insights-and-innovation/insights/logistics-trend-radar.html

www.gartner.com/en/supply-chain/insights/power-of-the-profession-blog/doing-more-with-less-quality-month-2023-and-supply-chain-risk

www.bcg.com/publications/2022/benefits-of-ai-driven-supply-chain

www.thomsonreuters.com/en-us/posts/technology/ai-supply-chains/

www.gartner.com/en/documents/4875831