This blog explores how Automation-as-a-Service empowers the Supply Chain & Logistics industry to excel in the complex 21st-century software landscape, covering the substantial impact and challenges faced while adopting automation. Our innovative product, OptimateIQ, with its flexible OPEX model adeptly bridges the longstanding gap that has stalled progress in this industry.

1. Introduction

Imagine a world where transportation and logistics flow seamlessly, where efficiency knows no bounds, and where your business operates at the peak of its potential. The business world has undergone a profound transformation, ushering in the era of “Everything”-as-a-Service. Gone are the days of hefty capital investments; now, you pay only for what you consume and when you consume it. The transition from on-premises to cloud has fundamentally reshaped the business landscape, shifting it from a capital-intensive infrastructure (CAPEX) model to a more agile, pay-as-you-go operational expenditure (OPEX) model. Surprisingly, this shift has been slow to reach the automation space.

In this era of Artificial intelligence and machine learning, where innovation is the driving force behind every industry, the concept of Automation-as-a-Service has emerged as a beacon of opportunity. It promises to revolutionize the way we conduct business, reshape our operational landscapes through software automation & RPA, and elevate our organizational capabilities to new heights, without a massive capital investment. As the demands for speed, accuracy, and scalability continue to grow, the need for a dynamic, cost-effective, and reliable automation solution is paramount.

“The Global Logistics Automation market size is projected to grow from USD 32.7 billion in 2023 to USD 51.2 billion by 2028, at a CAGR of 9.3% during the forecast period. The digital transformation across logistics industry will drive the market.” – Markets and Markets Report

2. The Present Operational Landscape in Supply Chain & Logistics

- Operational Costs: The Supply Chain & Logistics industry operates on particularly thin profit margins. Every operation, whether it’s tracking shipments, managing inventory, or handling customer requests, has a direct cost associated with it. Investing in automation solutions for on-time processing and operational efficiency can be financially burdensome, especially for SMBs and startups that struggle to allocate substantial budgets.

- Scalability Challenges: One of the perennial challenges faced by the T&L sector is scalability. As they face seasonal demands, they often need to rapidly expand their operations. Traditional manual processes and infrastructure limitations make scaling up a complex and costly endeavor.

- Limited Availability of Skilled Resources: The Supply Chain & Logistics sector has historically faced challenges in attracting and retaining skilled professionals with expertise in automation, data analysis, and technology implementation. The shortage of these resources can delay the adoption of automation and limit the industry’s ability to leverage advanced technologies effectively.

- Infrastructure Constraints: The Logistics industry relies on extensive physical infrastructure, from warehouses and distribution centers to transport fleets and cargo hubs. Capital investments in these infrastructures cannot be easily reconfigured or locked into software solutions. Implementing new technologies often requires integrating them with existing infrastructure, which can be complex and costly.

- Budgetary Considerations: The capital-intensive nature of the Supply Chain & Logistics industry means that significant financial resources are already allocated to the procurement and maintenance of existing assets. This leaves limited room for additional investments in software or automation tools. Allocating budgets for new technologies & their licenses without compromising the core operational functions requires careful financial planning and a clear understanding of the potential ROI.

- Resistance to Change: Change management can be a significant challenge in the logistics industry. Long-established manual processes are deeply ingrained in the culture, and there may be resistance to embracing business process automation and digitization.

Addressing these challenges requires a strategic approach and involves selecting automation solutions that can integrate seamlessly with existing processes and infrastructure. It should also focus on delivering tangible benefits in terms of efficiency, cost reduction, and competitive advantage.

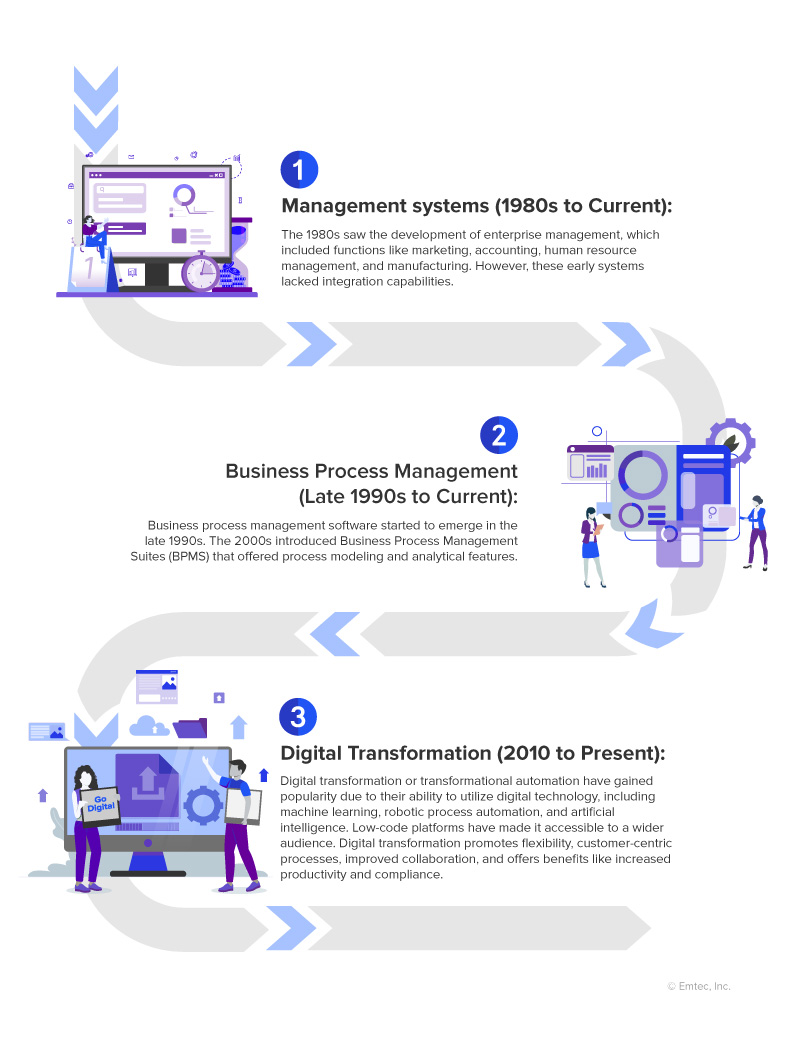

3. The Evolution of Business Automation

The innovation in business process automation began evolving from the 80s and there was no looking back. Following are the different phases of adoption of automation by businesses:

Artificial Intelligence & Machine Learning: In the contemporary business landscape, Artificial Intelligence (AI) and Machine Learning (ML) have emerged as transformative forces, reshaping the way organizations operate and engage with their stakeholders. This technological shift, witnessed from the early 2010s to the present day, has enabled companies to harness the potential of AI and ML to optimize processes, automate tasks, and gain insights from the available vast datasets. AI and ML applications, often integrated with existing software infrastructure, help in automating processes and workflows and empower businesses to adapt swiftly to changing customer expectations, enhance customer experiences, and deliver agile operations.

However, the logistics industry, in particular, still remains cautious in fully embracing AI and ML technologies due to the substantial investment required and an unclear vision for their implementation. You require a versatile solution capable of adapting to a wide range of logistics workflows, accommodating unique requirements, and seamlessly integrating automation in processes. Automation-as-a-service is just the right solution in this scenario, here’s how:

4. Understanding Automation-as-a-Service

Automation-as-a-Service platform that simplifies your automation journey. Everything from design and development to ongoing workflow monitoring and maintenance is taken care of, allowing you to concentrate on core business priorities. The goal is to deliver solutions that enhance productivity, efficiency, and remove the prerequisites and barriers to adopt automation at scale.

The platform comes with industry-specific workflows recipes that can be rapidly configured and tailored to align with your unique requirements, making the adoption of process automation more accessible than ever.

Many leaders are reluctant to pursue their innovative ideas because of the upfront investment required. For instance, you might have a groundbreaking idea that you’re eager to explore, but if the costs associated with licensing and infrastructure prove to be prohibitive, it can hold back the overall innovation process without even realizing it’s benefits.

But to completely fit into your existing Supply Chain & Logistics suite, you require a versatile solution capable of adapting to a wide range of logistics workflows, accommodating unique requirements, and seamlessly integrating automation into processes.

Introducing OptimateIQ, an Automation-as-a-Service platform…a no-nonsense service model tailor-made for the organizations struggling to focus on a bigger picture. What sets us apart is our revolutionary pay-per-transaction model, where you pay only for the transactions we process, precisely when you use them. We remove the complexities associated with capital investment for development, licensing, monitoring, maintenance, and infrastructure, making it easier for you to scale automation throughout your organization.

5. What is Pay-per-transaction Model?

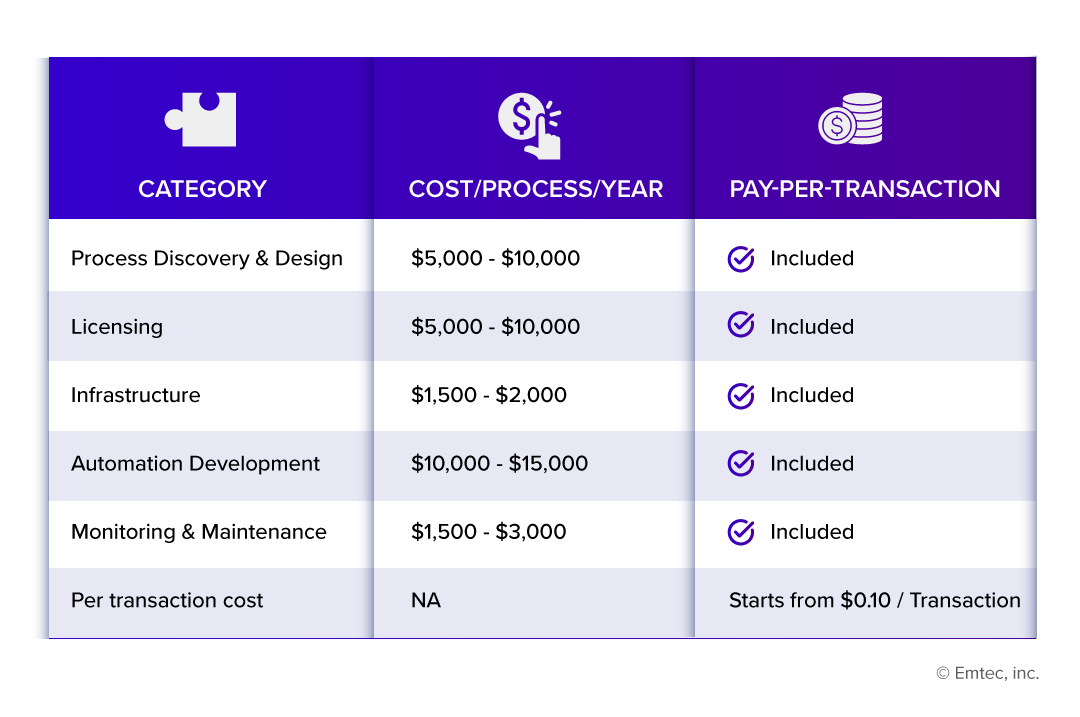

Let’s understand this difference between fixed cost investment mode (CAPEX) vs. Pay-per-transaction model (OPEX):

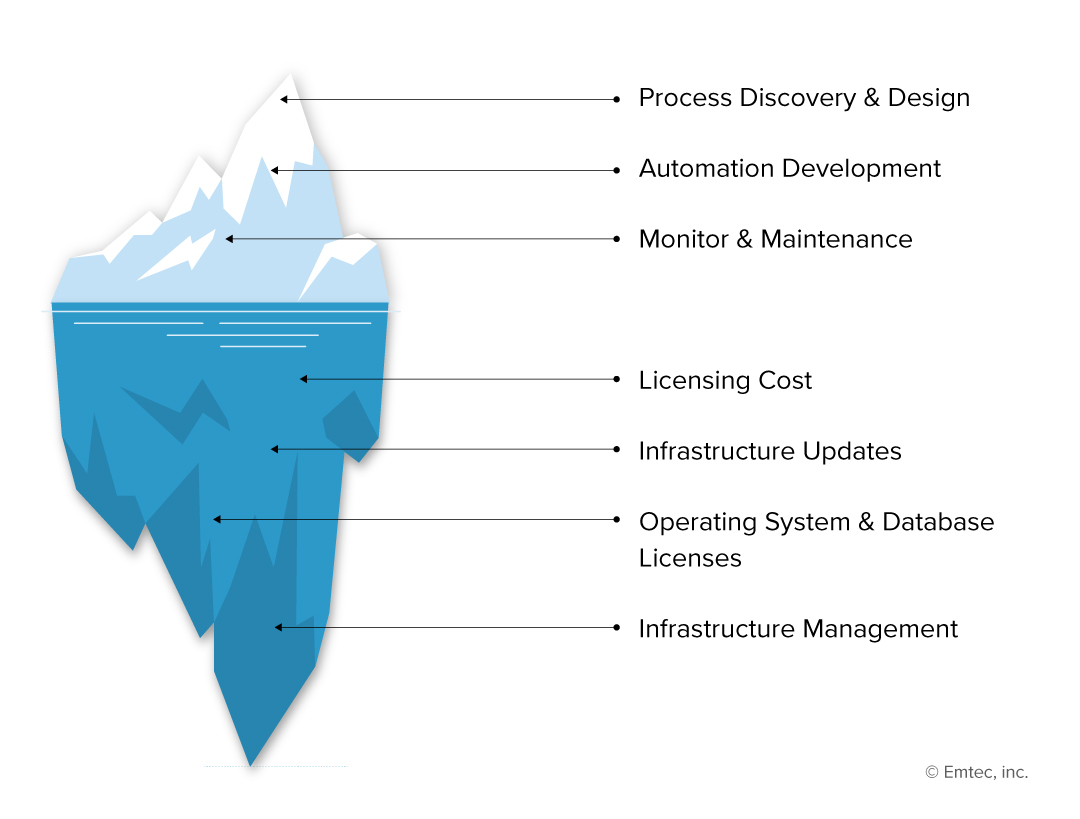

While Supply Chain & Logistics organizations can undoubtedly enjoy significant ROI advantages from independently implementing workflow automation, there are underlying costs that might not be readily visible which will negate the ROI benefits in long run.

The project cost can go beyond the initial software development and subscription fees. By accounting for these costs, business leaders can make informed choices about whether to make upfront investments or collaborate with service providers offering a Pay-per-transaction model. Our innovative Pay-per-Transaction service model is something which customers are charged based on the number of individual transactions.

Example – When automating invoice processing, you are billed based on the number of invoices processed. If you process 500 invoices in one month and 1,000 the next, your costs align with your transaction volume.

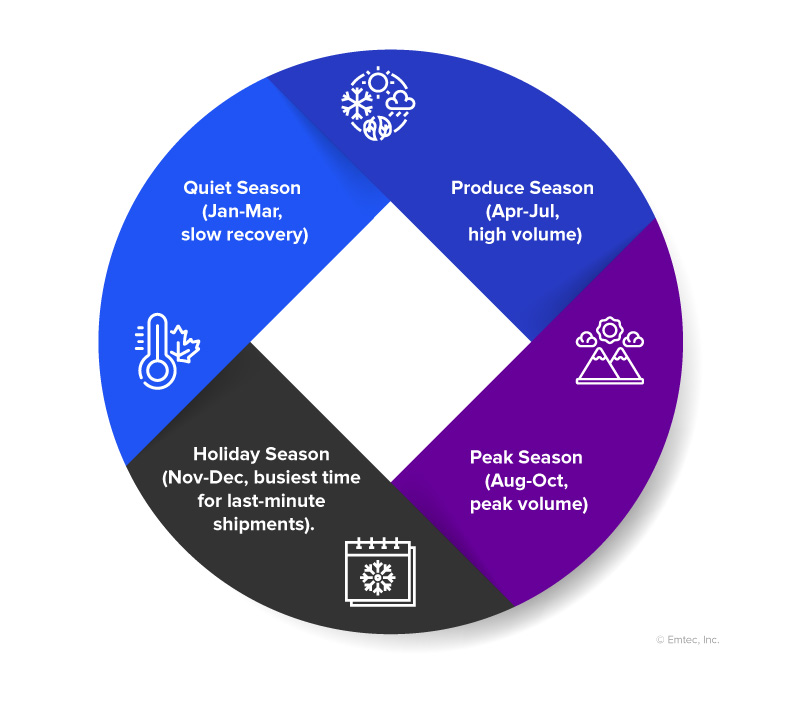

It is even better for the T&L industry since it faces seasonal market shifts impacting resources and business which goes through four seasons:

These seasonal variations impact rates and competition among carriers. Pay-per-Transaction model has proved to be extremely valuable for businesses as it aligns costs with usage levels and provides more flexibility in managing expenses.

6. Integrating OptimateIQ with Existing Systems

Adopting Automation-as-a-Service and integrating it with existing workflow involves combining a third-party automation service platform with your current software and hardware infrastructure to streamline and enhance your processes. Your automation partner usually begins by assessing your current systems, workflows, and operational needs to identify areas where automation can provide the most value. Based on the size and requirement of the project, right number of resources are allocated, software/hardware compatibility is verified, and then design, development, licensing, monitoring, and maintenance is done as needed. A trusted provider always ensures to maintain detailed documentation of the integration process, configurations, and any custom development. This documentation is crucial for troubleshooting and future reference.

OptimateIQ allows a seamless transition from Human-out-of-the-Loop (HOOL) to Human-in-the-Loop (HITL), ensuring data accuracy through human verification and adjustments when needed. This harmonious combination of Digital workers (aka Bots) with the precision and expertise of Knowledge workers (aka Humans) provides the highest quality results and better business outcomes. We collaborate closely with our esteemed partners SMC3, MileMaker, and TextLocate to deliver the pinnacle of logistics automation solutions for your business.

7. Future-proofing Business with Automation-as-a-Service: Use Cases in Supply Chain & Logistics Industry

OptimateIQ’s Automation-as-a-Service is emerging as a pivotal solution to overcome these longstanding issues and drive the Supply Chain & Logistics industry toward a more efficient and sustainable future.

Here are some use cases that proves its significance in Supply Chain & Logistics:

⮞ Appointment Scheduling: 100+ appointment scheduling applications and no standard in the scheduling process makes this one of the highly cumbersome and labor-intensive operations, requiring teams to check with clients through email / phone / website for suitable pickup and delivery slots. This is followed by cross-checking with internal systems to acquire information on purchase orders, truck location, and driver availability. And lastly entering the data into the system of records. All this can take anywhere between 10 minutes to 30 minutes to book a single appointment. RPA helps to streamline highly complex appointment scheduling process, allowing carriers/3PLs to update the TMS or any system of records without any manual intervention.

⮞ Load Board Posting: Ensuring the availability of the right carriers to move loads is a critical success imperative for logistics companies. Shippers and 3PLs post their loads on several load boards to ensure a wider outreach. Connecting with hundreds of carriers using manual methods can be an extremely laborious task, leading to time and cost inefficiencies. RPA facilitates load posting on multiple load boards from one central location with a single click. This level of automation helps shippers and 3PLs access hundreds of individual load boards and other carrier applications at no additional cost or effort.

⮞ No-touch Automation Solution: A global freight forwarding company wanted to automate customs clearance processes that included error-free document submissions, declarations which were very time consuming and repetitive. They employed no-touch automation solution for document processing workflow and paid just for the number of documents processed. This eliminates the risk of errors, accelerates document processing, and ensures compliance with regulations, enabling the logistics company to provide faster and more accurate services to its clients.

⮞ Seasonal Scalability: A seasonal freight company faces fluctuations in shipment volumes during peak seasons. They struggled with spikes in order processing, leading to backlogs and resource constraints. By automating order processing workflow, they achieved seasonal scalability, customer communication, load management & route optimization. With Pay-per-transaction model, they were able to seamlessly scale up during high-demand periods and scale down during quieter times. As a result, they optimized resource allocation, reduced operational costs, and maintained consistent service quality throughout the year.

⮞ Carrier Onboarding and Compliance: Onboarding carriers and ensuring they meet the strict compliance mandates prescribed by the Federal Motor Carrier Safety Administration (FMCSA) is a critical function in freight logistics. Done manually, carrier onboarding and compliance is an incredibly time-consuming process with multiple forms and laborious paperwork. RPA improves quality and on-time delivery by enabling better carrier audit and compliance records such as CAS, Insurance, SAFER & ELD logs. Compliance mandates and validation rules are pre-built into bots, thereby ensuring adherence to rule-based criteria at every touch point. Automation allows carriers and brokers to share freight data in real time across Verified Carrier Aggregator Platforms to streamline carrier onboarding. Watch a video on automation for efficient carrier onboarding and compliance.

⮞ Carrier Invoice Validation: Managing invoices is challenging, necessitating reconciliation of multiple documents such as Bill of Lading while dealing with various charges including detention fees, seasonal surcharges, accessorial charges, etc. Accounts payable teams need to compare invoice projections with the actual invoices received, map these amounts with the relevant documentation, and upload the final documents in the TMS. This is extremely time-consuming and causes delays in invoice settlement.

⮞ Automated Order Processing & Tracking: A global supply chain provider wanted to stay ahead of its curve by encompassing automation in order processing. But investing in high-quality software solutions and skillsets was a big challenge. They leveraged Automation-as-a-Service platform for real-time order processing workflow & shipment tracking. It enabled quicker order fulfillment, reduced errors, and enhanced customer service, setting them apart from competitors in the highly competitive logistics industry.

8. How OptimateIQ Can Help you Kickstart your Automation Journey

Reckon you’re at the forefront of the Logistics business world, ready to embrace automation, but weighed down by the risk of significant upfront investments. Enter OptimateIQ’s Automation-as-a-Service platform – your key to a future of efficiency and competitiveness. With specialized platforms such as Bot as a Service, Conversation as a Service, and Copilots, we prioritize delivering automation solutions that elevate your operational landscape. Our exceptional model offers a pay-per-transaction approach, ensuring you pay only for the resources you use exactly when you need them, removing complexities associated with capital investments and facilitating widespread automation adoption. Our profound domain knowledge, combined with Design Thinking principles, ensures superior solutions tailored to your varied automation requirements. Advance your business workflows effortlessly with our no-touch automation solution.

The future of your business begins with a personalized consultation – contact us today and watch your automation journey take off.

References

www.automationanywhere.com/company/blog/thought-leadership/unveiling-2023-automation-now-next-report

www.ibm.com/resources/automate/process-mining-and-rpa-automation-power-couple

www.researchgate.net/publication/225932655_The_Scope_and_Evolution_of_Business_Process_Management